Introduction to Diamond Wire Cutting

The demolition industry has undergone significant innovation over the past decade, primarily driven by the demand for safer, more environmentally friendly, and highly accurate methods to dismantle resilient structures. One of the standout advancements is diamond wire cutting, where diamonds embedded in a steel wire are used to slice through dense materials, such as reinforced concrete, steel, and stone, with ease and precision. As highlighted by https://bluegrassbit.com/, this technology allows contractors to tackle both massive infrastructure projects and highly specialized demolition tasks efficiently. In contrast to traditional demolition techniques, which often produce significant noise, dust, and disruption, diamond wire cutting offers a cleaner, quieter solution with exceptional accuracy.

How Diamond Wire Cutting Works

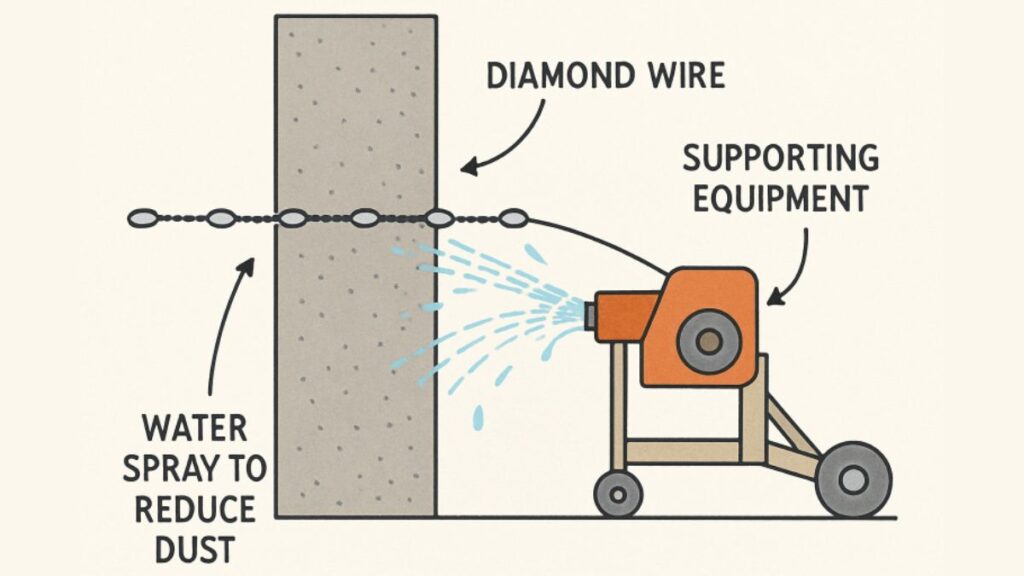

At its core, diamond wire cutting employs a flexible steel cable intricately set with diamond segments. This wire is threaded around or through challenging materials to outline the intended cut. Once in place, hydraulics or electric motors drive the wire at high speeds, allowing the diamond segments to grind through barriers efficiently. To further enhance operational safety and effectiveness, water or coolant streams are directed over the cut site throughout the process. This addition limits heat buildup, minimizes dust emissions, and provides a cleaner working environment for crews. As highlighted by MarineLink, this technique has proven particularly valuable in complex demolition scenarios where precision and environmental safety are paramount.

Unlike percussive methods such as jackhammering or traditional sawing, diamond wire cutting produces almost no vibration—an essential advantage when managing projects near fragile historical buildings, active business operations, or within dense urban environments. The result is a demolition process marked by surgical accuracy and vastly reduced collateral damage.

Advantages of Diamond Wire Cutting

- Precision: The diamond-embedded wire delivers extremely accurate cuts with minimal material loss, which is vital for projects requiring reusable or salvageable components.

- Versatility: This approach effectively handles a wide array of materials, from concrete beams to massive steel supports and dense natural stone, making it ideal for multifaceted demolition challenges.

- Reduced Noise and Vibration: The almost silent operation helps mitigate environmental disturbances, providing additional safety and comfort for nearby workers and residents.

- Environmental Benefits: Diamond wire cutting generates significantly less dust and debris, supporting site cleanliness and reducing hazardous emissions compared to older techniques.

Applications in Demolition Projects

The versatility of diamond wire cutting is showcased in diverse demolition scenarios, particularly where precision and safety are paramount. For example, one landmark project in Brisbane, Australia, involved the deconstruction of a major wharf. In this endeavor, diamond wire saws cleanly severed more than 200 massive steel and concrete piles—some measuring over a meter in diameter—within four months. This feat underscores the technique’s dependability for sustained, high-stress usage across commercial, municipal, and marine construction settings.

Safety Considerations

Safety is paramount in all demolition activities, and diamond wire cutting is no exception. Operators should undergo rigorous training to ensure proper equipment handling and workflow safety. Essential personal protective equipment (PPE), such as cut-resistant gloves, eye protection, and hearing protection, must be standard on every site. Furthermore, diligent maintenance—such as inspecting the wire for wear and keeping coolant systems functioning—is vital in preventing accidents and maintaining optimal operational performance. For more guidance, the Health and Safety Executive (HSE) provides a helpful framework in its safety standards. These practices not only protect workers but also help maintain project efficiency by reducing downtime caused by equipment failures. Ultimately, a strong safety culture ensures that precision cutting methods, such as diamond wire cutting, can be applied effectively and responsibly.

Environmental Impact

Traditional demolition tools frequently leave behind clouds of dust, hazardous debris, and a noisy, high-vibration environment. In contrast, diamond wire cutting offers substantial environmental advantages. The continuous water-based cooling system serves not only to extend the lifespan of the wire and machine components but also to capture and neutralize dust before it disperses, thereby maintaining air quality for both workers and the surrounding neighborhood. Because the process produces minimal waste material, site cleanup is more manageable, and recycling becomes feasible, supporting broader sustainability goals within the construction industry.

Technological Advancements in Diamond Wire Cutting

Modern diamond wire saws feature significant advancements over their predecessors. Digital automation and remote operation capabilities now enable technicians to manage equipment from a safe distance, reducing exposure to potentially hazardous situations and increasing workflow efficiency. Intelligent control systems can also track wear and usage in real-time, reducing downtime by optimizing maintenance schedules. Eco-friendly cooling options that recycle water and leverage filtration technology further augment the industry’s push towards greener demolition practices. These improvements not only support sustainability but also reduce job costs by maximizing productivity and minimizing resource consumption.

Conclusion

Diamond wire cutting is redefining what is possible in the world of demolition. By providing unmatched precision, operational versatility, low environmental impact, and advanced automation features, this technique ensures safer job sites and cleaner project outcomes. Given its broad applicability and ever-evolving technology, diamond wire cutting stands at the forefront of responsible demolition—equipping contractors to tackle both present-day infrastructure challenges and the sustainability demands of the future.